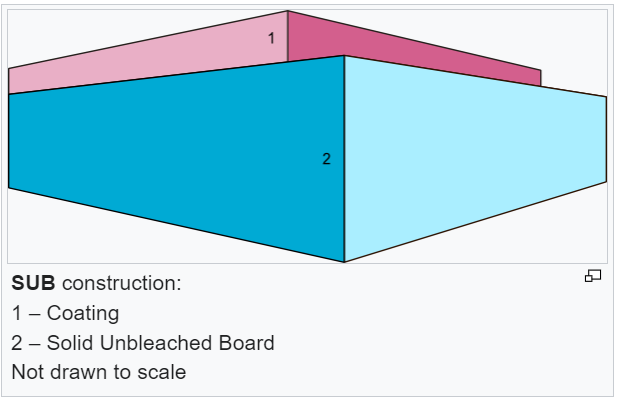

Product details

Solid Unbleached Board (SUB) is a robust and environmentally friendly paperboard made from unbleached virgin wood pulp. Known for its natural brown color and high strength, SUB is widely used in packaging applications where durability, sustainability, and cost-effectiveness are key considerations. Its strength and resilience make it ideal for heavy-duty packaging, while its eco-friendly nature appeals to brands and consumers focused on sustainability.

Key Features and Benefits

- Natural Appearance: SUB has a natural brown color that conveys an eco-friendly and organic look, making it popular for brands aiming to highlight sustainability.

- High Strength and Durability: The unbleached fibers in SUB give it superior strength and rigidity, providing excellent protection for heavy or bulky products.

- Cost-Effective: With its strong structure and lower processing requirements, SUB offers a cost-effective packaging solution without compromising on quality.

- Eco-Friendly: Made from unbleached, recyclable materials, SUB is a sustainable choice. It often comes from responsibly managed forests and is fully recyclable and biodegradable.

- Versatile Applications: SUB is easily cut, folded, and glued, making it suitable for various packaging forms, from boxes and cartons to trays and inserts.

- Moisture Resistance: While SUS naturally provides some moisture resistance, it can be enhanced with coatings like polyethylene (PE) or wax for food packaging applications.

- Grease and Oil Resistance: Coated SUS can also offer grease resistance, making it suitable for products such as fast food trays or grease-prone items like meats and fried foods.

- Creasability: SUS has excellent folding and creasing properties, making it ideal for converting into folding cartons and boxes. It folds without cracking, even at higher thicknesses.

- Folding Endurance: SUS offers good endurance during the folding process, depending on the thickness and GSM, maintaining its integrity over several folding cycles.

Applications of Solid Unbleached Board

- Heavy-Duty Packaging: SUB is ideal for packaging that requires extra strength, such as industrial goods, electronics, and automotive parts.

- Eco-Friendly Packaging: Often used in products where an organic or rustic appearance is desired, such as in food and beverage packaging, especially for organic or artisanal products.

- Shipping Containers: The strength and rigidity of SUB make it a popular choice for shipping containers and corrugated boxes, where durability is critical.

- Retail Packaging: SUB is increasingly used in retail packaging to create a natural and environmentally conscious image, particularly in sectors like health and wellness, and organic products.

- Frozen and Chilled Food Packaging: Provides durability and resistance to moisture.

- Beverage Carriers: Strong enough to hold heavy liquid containers.

- Detergent and Cereal Boxes: Offers the strength and rigidity needed for bulk products.

- Footwear and Toy Packaging: Used for packaging that requires sturdy protection during transportation and storage.

Environmental Considerations

Solid Unbleached Board is a sustainable packaging material, made from unbleached pulp that requires less processing, reducing its environmental impact. It is fully recyclable and biodegradable, making it an excellent choice for brands committed to reducing their carbon footprint. Many SUB products are certified by organizations such as the Forest Stewardship Council (FSC), ensuring that they meet strict environmental and social standards.

Conclusion

Solid Unbleached Board (SUB) offers a perfect balance of strength, sustainability, and cost-effectiveness. Its natural appearance and superior durability make it an excellent choice for various packaging needs, from heavy-duty industrial packaging to eco-friendly consumer goods packaging. For brands looking to combine functionality with environmental responsibility, SUB is the material of choice.