Product details

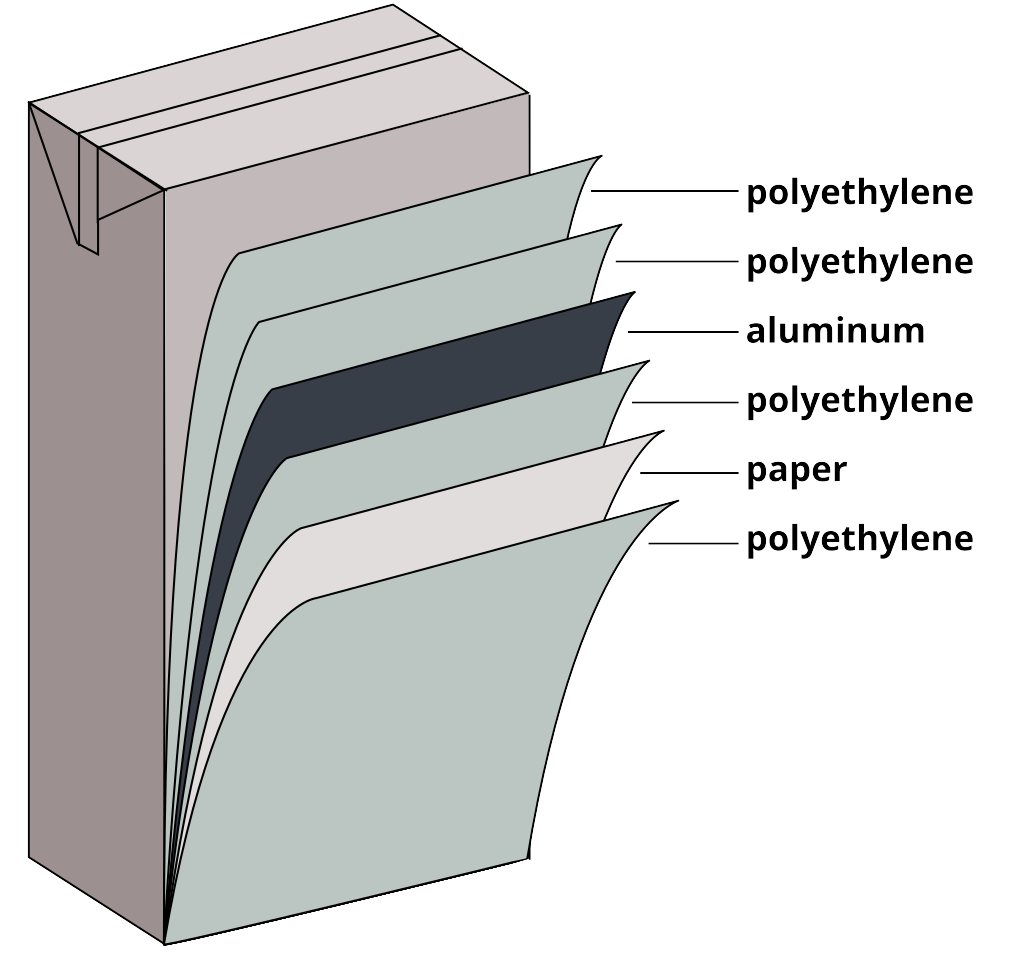

1. Structure:

- Multi-Layered Construction: Typically consists of multiple layers, including:

- Base Layer (Paperboard): Provides the strength and rigidity required to support the liquid contents.

- Polyethylene (PE) Coating: Offers water resistance and ensures that the liquid does not leak or compromise the integrity of the board.

- Aluminum Foil Layer (Optional): Used as a barrier to light, oxygen, and odors, particularly for long-life liquids (aseptic packaging).

- Additional PE Layers: Protects both the inner and outer surfaces of the packaging, preventing moisture ingress or egress.

2. Grammage (Basis Weight):

- The weight of the board varies depending on the liquid and packaging format, typically ranging from:

- 170 GSM to 350 GSM for single-use packaging.

- Heavier weights up to 400 GSM for more durable, larger packaging.

3. Thickness (Caliper):

- Standard Thickness: Ranges from 300 microns to 600 microns, depending on the desired rigidity and the amount of liquid the board will hold.

- Thin Grades (300-350 microns): Used for small-volume packs like juice boxes (200ml-500ml).

- Thicker Grades (400-600 microns): Used for larger containers like 1-liter milk or juice cartons.

4. Barrier Properties:

- Moisture Resistance: Achieved through polyethylene (PE) coatings on both the inner and outer surfaces to protect against water absorption and maintain the integrity of the packaging.

- Oxygen & Light Barrier: Aluminum foil or EVOH (ethylene vinyl alcohol) is often used for aseptic packaging to extend shelf life by preventing oxygen and light from degrading the product.

- Gas Permeability: The aluminum or barrier layer ensures minimal transmission of gases like oxygen and carbon dioxide, preserving the freshness of the liquid contents.

5. Coatings & Lamination:

- Polyethylene Coating (PE): Applied on both sides of the board, providing excellent heat-sealability and preventing liquid penetration.

- Standard PE thickness ranges from 12 to 50 microns depending on the application.

- Aluminum Foil (Optional): Thickness typically ranges from 6 to 10 microns, offering a strong barrier to light and oxygen in aseptic packaging.

- EVOH Layer (Optional): Provides a gas barrier when aluminum is not used, particularly for more eco-friendly options.

6. Strength & Durability:

- Stiffness: High stiffness levels ensure that the packaging retains its shape even when filled with liquid.

- Typical stiffness values are in the range of 3-10 mN.m depending on the grade and application.

- Tensile Strength: LPB offers strong tensile strength to prevent tearing or breakage during handling, processing, or transport.

- Tensile strength generally ranges from 3.5 to 7.0 kN/m.

7. Printability:

- Surface Coating: The outer PE coating allows for high-quality printing using flexographic or offset printing techniques.

- Print Types: Full-color printing, often using food-safe inks, allows for vibrant and detailed packaging designs that enhance brand visibility.

8. Heat Sealability:

- The PE coatings provide excellent heat-sealing properties, ensuring that the packaging is leak-proof and tamper-resistant after filling.

- Heat seal temperature typically ranges from 120°C to 150°C, depending on the type of PE used.

9. Food Contact Safety:

- LPB is manufactured to comply with stringent food contact safety standards, ensuring no harmful substances migrate from the packaging into the liquid.

10. Recyclability & Sustainability:

- Recyclable: LPB is designed to be recyclable, with many variants made from FSC (Forest Stewardship Council) certified materials.

- Biodegradable & Compostable Options: Some LPB products offer biodegradable or compostable coatings, such as bio-based PE or PLA (polylactic acid), for more eco-friendly packaging solutions.

11. Sizing & Formats:

- Available in a variety of formats to accommodate different liquid volumes, ranging from 100 ml to 2 liters.

- Rolls or Sheets: LPB can be supplied in rolls or pre-cut sheets, depending on the packaging machinery used.

12. Key Performance Indicators:

- Moisture Vapor Transmission Rate (MVTR): A critical factor for liquid packaging, typically less than 5 g/m²/24hr to ensure no moisture loss or gain.

- Oxygen Transmission Rate (OTR): For aseptic packaging, the aluminum or barrier layer ensures OTR levels are extremely low, often less than 0.1 cc/m²/24hr.

- WVTR (Water Vapor Transmission Rate): PE layers ensure WVTR remains below 5 g/m²/24hr for most liquid packaging applications.

13. Customization Options:

- Shapes & Sizes: The board can be cut and folded into various shapes to create tetra packs, gable tops, and other liquid container formats.

- Printing & Branding: Full-color printing with customization options for product branding, nutritional information, and design.

14. Applications:

- Dairy Products: Commonly used for milk, yogurt, and cream packaging.

- Juices & Beverages: Suitable for juice boxes, flavored waters, and soft drinks.

- Soups & Liquid Foods: Often used for packaging ready-to-heat soups and liquid food products.

- Aseptic Packaging: For long-life liquids such as UHT milk, fruit juices, and other shelf-stable products.